Why are screen contact tests required annually?

Inspection of cassettes for good film screen contact is an often overlooked yet important quality control procedure. Poor film/screen contact can be the reason for areas of increased density, reduced density and blurring. The film that you install into your cassette is not exposed solely by radiation. It is exposed by the screens within the cassette that glow when hit by radiation. If these screens are dirty or are not in good contact with the film, they can yield poor radiographs that can possibly lead to a mis-diagnosis of a patient’s condition.

Some states, like Minnesota, require screen contact testing on an annual basis. We perform this testing using a screen contact test tool which is a flat device that is about 14″ x 17″ consisting of a wire mesh encased in plastic.

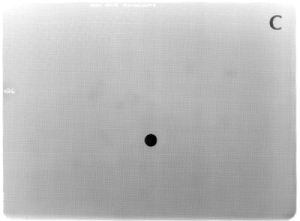

We place the test tool on top of your cassette. Using an intra-oral, we make a uniform exposure that covers the entire cassette surface. After that, we process the film. If the film has a uniform density with a solid grid pattern and does not show areas of fogging, spotting, or blurring then it passes. Below is an example of a good screen contact test:

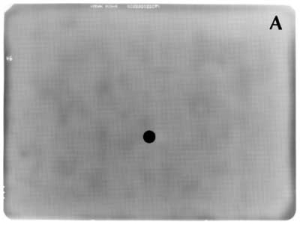

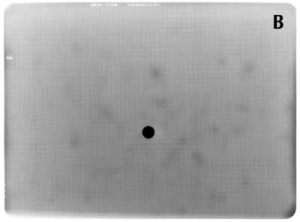

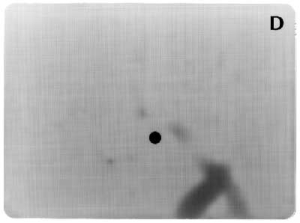

And here are some examples of tests that have failed for various reasons.

Poor screen film contact can sometimes be corrected by cleaning the screens using an anti-static intensifying screen cleaner such as Kodak’s Anti-static Intensifying Screen Cleaner which comes in a pump spray bottle. You clean cassette screens by moistening a lint-free wipe with a small amount of screen cleaner, then rubbing the screens with the wipe. Always remember to allow the screens to dry completely before re-testing. Avoid any excessive rubbing, abrasive gauze, pouring of any solution directly onto the screens, or using an excessive amount of solution. If cleaning does not work, screen replacement would be the next step. If that does not work due to worn out cassette seals or flattened foam backings then the cassette itself will need to be replaced. Judging by how the screen test fails and how the cassette seals/foam backing look, we are normally able to recommend the course of action that will get your cassette to pass again.

We have an informational sheet from the MDH on the subject of screen contact testing available here:

https://www.rtechdental.com/documents/mnscreentest.pdf

Kodak also has a good informational page on screen contact testing, although it deals more with screen testing for mamography: